1.Replacing three discs with a single disc, it has a lower failure rate and is easy to operate.

2.Fully automatic continuous process, with precise positioning and stable operation.

3.Customizable from 16-22 oz, suitable for single and double laminated paper cups.

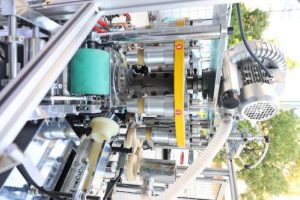

The working principle of the paper cup machine is that a main motor drives the whole machine to realize the perfect integration of gear and cam structure.Now the machine uses a single aluminum disk instead of the previous three-disk machine, greatly reducing the failure rate of the machine and reducing the training time for the operators.A 3-16oz odd-even shower film paper cup can be made according to customer request.Is a automatic paper cup molding equipment, through rows of automatic paper, paper device (ensure accurate positioning), ultrasonic or copper welding, mechanical paper transfer, oil injection, bottom, folding, preheating, rolling, cup, unloading continuous process, can stabilize the production of different specifications of paper cup, is our company after comprehensive technical improvement to improve the stability of the paper cup equipment.

| Model | HF-DP22 |

| Production speed | 50 to 70 minutes 50-70 pcs/min |

| Voltage | 380V / 50Hz three-phase |

| Machine package size | 2300x1200x1800mm (Length * Width * Height L*W*H) |

| material requirements | Both single-sided and double-sided laminated paper are available. |

| Power | 7kw |

| Weight | 2000Kg |

| Corresponding to the paper cup size | 16oz-22oz |

| speed | 50-70pcs/min |

| Paper thickness requirements | 150-300g/㎡;±20g/㎡ |

| Gas supply requirements | 0.6-0.8mpa;0.4m³/min |

| Machine size of machine machine machine | 900x600x1800mm (Length * Width * Height L*W*H) |

| The cup body sticks in | ultrasonic |

| Bottom rolling flowers | Blowing heating |

| Molds can be customized according to customer requirements at extra cost | |