1.Desktop layout separates the transmission mold, making cleaning and maintenance convenient.

2.Precise transmission combined with automatic lubrication ensures stable and reliable operation of the entire machine.

3.PLC intelligent control, with production capacity ranging from 120 to 160 units per minute.

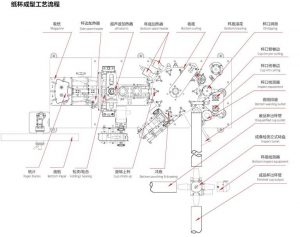

The HF-160S smart paper cup machine uses a desktop layout that isolating the transmission parts and molds. The transmission parts are under the table and the mold on the table, this layout facilitates cleaning and maintenance. The machine adopts automatic spray lubrication, longitudinal shaft drive structure, barrel cylindrical dividing mechanism and gear transmission, to ensure the stability and quality of the whole machine. For electrical components, use PLC, photoelectric tracking and servo feed. The machines have a production capacity of up to 120-150 / min and are suitable for producing 5-16 oz cold / hot cups.

| High-speed Intelligent Paper Cup Machine HF – 160S | |

| weight | 4000 kg |

| packing without carton | Length: 2800mm x Width: 1100mm x Height: 1800mm |

| power configuration | Three-phase 380V, 25KW |

| Compressed air configuration | 0.6-0.8MPa,0.5m³/min |

| production capacity | 120-160 pcs/min |

| paper type | Single and double PE/PLA |

| paper gsm | 210-330g/㎡ |

| Cup size specification | (D1 cup opening) 50 – 90mm (D2 cup bottom) 45 – 65mm (H cup height) 60 – 138mm (h bottom depth) 5 – 12mm |

| detection device | (Optional) |

| Control panel | 7 inches |

| collection table | 1000 x 650 x 1600mm |