1.Complete multiple processes at once, with an efficient and seamless bag-making process

2.Full servo drive + CPU control, easy adjustment, stable operation

3.Suitable for various types of paper bags, applicable in fields such as food and medical use

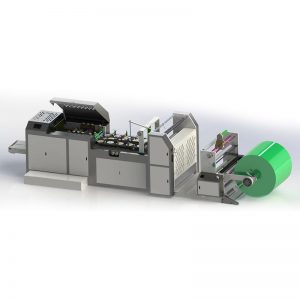

This machine is used for one-time completion of gluing and film application on rolls of original color paper or printing rolls such as kraft paper, glossy paper, medical paper, etc. It can glue on the top, form a tube, cut off, apply glue at the bottom, shape the bag, count and collect the pointed-bottom paper bags. The overall structure of this machine is reasonable, compact, and easy to adjust. It is controlled by a high-speed moving central processor, fully servo-driven, with touch screen display, and servo motor controls the bag-making speed. It is an ideal equipment for producing various types of paper bags, food bags, fast food bags, bread bags, medical bags, dried fruit bags, shopping bags, etc., which are environmentally friendly paper bags.

| Machine model | HF-JD260 | HF-JD350 |

| Bag cutting length | 120-400mm | 225-710mm |

| Bag making length | 100-380mm | 215-700mm |

| Bag making width | 80-250mm | 80-350mm |

| Edge insertion size | 0-100mm | 0-110mm |

| Trough height | 15mm | 15-18mm |

| Bag production speed | 100-600pcs/min | 100-500pcs/min |

| Paper width | 160-780mm | 220-1050mm |

| Maximum diameter of paper material | 1000mm | 1000mm |

| Inner diameter of paper material | 76mm | 76mm |

| Thickness of paper material | 45-80g/m2 | 45-80g/m2 |

| Working air source | >0.12m3 /min, 0.5-0.8mpa | >0.12m/min,0.5-0.8mpa |

| Overall machine power | 380v 3phase 4line 12kw | 380v 3phase 4line 12kw |