1.The roll paper is formed in one step, and the paper bag process is fully automated.

2.The sealing and gluing are completed all the way to the bottom, with an efficient and stable process.

3.It is applicable to various types of eco-friendly paper bags and has a wide range of applications.

This machine can complete the paper bag production process for roll-type original color paper or printing roll-type paper such as kraft paper, food paper, etc. in one go. It features automatic middle sealing, raw material rolling, fixed-length cutting, bottom embossing, bottom folding, bottom gluing, and bag bottom shaping. The finished bags can be processed all at once. This machine is more convenient to operate, more efficient, and more stable. It is a machine equipment for producing various types of paper bags, such as eco-friendly paper bags for snacks, bread bags, dried fruit bags, etc.

| Machine model | HF-FD220B | HF-FD330 | HF-FD450 |

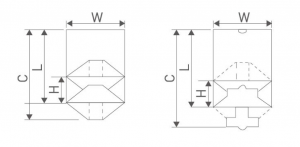

| Bag cutting length | 190-430mm | 270-530mm | 270-530mm |

| Paper bag width | 80-220mm | 150-330mm | 220-430mm |

| Bag bottom width | 50-105mm | 60-180mm | 90-180mm |

| Paper bag thickness | 50-150g/m2 | 60-150g/m2 | 80-150g/m2 |

| Machine speed | 30-260pcs/min | 30-220pcs/min | 30-220pcs/min |

| Paper bag speed | 30-200pcs/min | 30-180pcs/min | 30-150pcs/min |

| Paper roll width | 290-710mm | 380-1050mm | 660-1290mm |

| Paper material diameter | 1300mm | 1300mm | 1300mm |

| Paper material inner diameter | 76mm | 76mm | 76mm |

| Overall machine power | 380V 3phase 4line 11.5kw | 380V 3phase 4line 15kw | 380V 3phase 4line 15kw |

| Overall machine weight | 6000kg | 8500kg | 9000kg |

| Overall machine size | 8200*3500*2200mm | 10000*3700*2200mm | 10000*3800*2200mm |