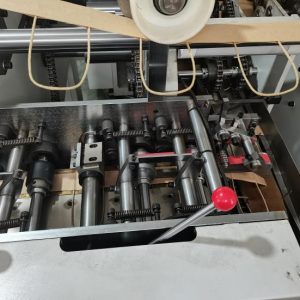

1. The Weller touch screen human-machine interface is adopted, making the operation functions clear at a glance and facilitating control.

2. The original Mitsubishi motion controller from Japan is used, and through integration with optical fibers, it ensures stable high-speed operation. 3. Utilize Mitsubishi servo motors from Japan combined with Schunk color sensor eyes from Germany to precisely track the size of the printed bags.

4. The raw material loading and unloading adopt a hydraulic-powered lifting structure, and the unwinding process uses a fully automatic constant tension control system.

5. The raw material deviation correction employs a brushless servo motor, reducing the adjustment time for paper roll alignment.

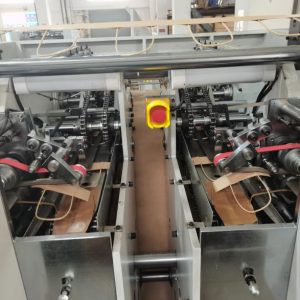

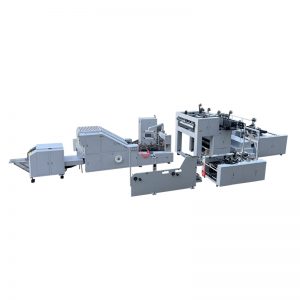

The fully automatic square-bottom paper bag machine is designed to use roll paper and paper strings as raw materials to produce hand-held square-bottom paper bags in one step. It is an ideal equipment for rapid production of hand-held handle bags. This machine is particularly suitable for producing environmental-friendly packaging paper bags for industries such as food bags and hand-held shopping bags. The machine completes the steps of hand handle fabrication, hand handle pasting, paper tube formation, paper tube cutting, and bag bottom formation in one go. It adopts the Japanese Mitsubishi high-speed motion controller (CPU) and controls the operation of the servo through a high-speed bus, ensuring stable movement, smooth movement curves, intelligent interface operation, and truly achieving full automation production. It can effectively save labor costs. It is the preferred fully automatic hand-held square-bottom paper bag equipment for those who produce hand-held bags such as food and clothing.

| Machine model | HF-FD220T | HF-FD350T | HF-FD450T |

| Cutting length of paper bag | 190-430mm | 270-530mm | 270-530mm |

| Cutting length of paper bag (total) | 190-350mm | 270-430mm | 270-430mm |

| Width of paper bag | 80-220mm | 150-330mm | 220-430mm |

| Width of paper bag (total) | 120-220mm | 200-330mm | 220-430mm |

| Bottom width of bag | 50-105mm | 60-180mm | 90-180mm |

| Paper bag weight | 70-140g/m2 | 60-150g/m’ | 80-150g/m’ |

| Paper bag weight (total) | 70-140g/m2 | 80-150g/m’ | 80-150g/m2 |

| Width of paper roll | 370-770mm | 380-1050mm | 650-1290mm |

| Width of paper roll (total) | 410-770mm | 570-1050mm | 690-1290mm |

| Diameter of paper material | 1300mm | 1300mm | 1200mm |

| Inner diameter of paper core | 76mm | 76mm | 76mm |

| Length of hand grip patch | 90mm | 152.4mm | 190.5mm |

| Width of hand grip patch: | 50mm | 50mm | 50mm |

| Spacing of paper rope | 57mm | 75mm | 95mm |

| Diameter of paper rope for hand grip: | 3-5mm | 3-5mm | 3-5mm |

| Width of paper roll for hand grip patch | 100mm | 100mm | 100mm |

| Diameter of paper roll for hand grip | 1200mm | 1200mm | 1200mm |

| Weight of paper patch for hand grip | 100-135g/m2 | 100-135g/m’ | 100-135g/m |

| Machine speed | 30-200pcs/min | 30-200pcs/min | 30-180pcs/min |

| Speed of paper bag | 30-180pcs/min | 30-180pcs/min | 30-150pcs/min |

| Speed of hand-held device | 30-180pcs/min | 30-150pcs/min | 30-130pcs/min |

| Cutting tool method | Saw-tooth cutting | Saw-tooth cutting | Saw-tooth cutting |

| Total power of the console | 380V/3Phase 4Line 28kw | 380V/ 3phase 4line 41.5kw | 380V/ 3phase 4line 41.5kw |

| total weight | 13000Kg | 15000kg | 15500kg |

| Overall machine size | 11000*4400*1800mm | 14000*6000*2400mm | 14000*6000*2400mm |