1.Desktop layout separates the transmission mold, making cleaning and maintenance convenient and efficient.

2.Precise transmission is stable and reliable, ensuring the quality of the finished product.

3.PLC intelligent control, with an output capacity of 120-140 pieces per minute.

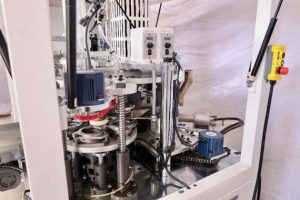

The HF-130S High-Speed Intelligent Servo Cup Machine features a desktop layout with isolated transmission components and molds. The transmission parts are positioned under the worktable while molds are mounted on the surface, facilitating easy cleaning and maintenance. The machine employs automatic spray lubrication, longitudinal shaft transmission structure, barrel-type cylindrical indexing mechanism, and gear transmission to ensure overall stability and quality. Electrical components utilize PLC control with photoelectric tracking and servo feed systems for operation. This equipment boasts a production capacity of 120-140 cups per minute, suitable for manufacturing hot/cold cups ranging from 3 to 9 ounces.

| High-speed intelligent servo paper cup machine HF – 130S | |

| weight | 2400 kg |

| packing without carton | Length: 2600mm x Width: 1300mm x Height: 1950mm |

| power configuration | Three-phase 380V, 15KW |

| Compressed air configuration | 0.6-0.8MPa,0.5m³/min |

| production capacity | 120-140 pcs/min |

| paper type | Single and double PE/PLA |

| paper gsm | 150-320g/㎡ |

| Cup size specification | (D1 cup opening) 50 – 80mm (D2 cup bottom) 40 – 65mm (H cup height) 50 – 92mm (h bottom depth) 5 – 10mm |

| detection device | (Optional) |

| Control panel | 7 inches |

| collection table | 1000 x 700 x 1600mm |