1.The desktop layout separates the transmission molds, making cleaning and maintenance more convenient.

2.Precise transmission combined with automatic lubrication ensures the stability and reliability of the entire machine.

3.PLC intelligent control, with an output capacity of 90-120 pieces per minute.

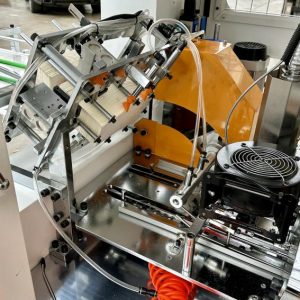

The HF-128S High-Speed Intelligent Cup Machine features a desktop layout that isolates transmission components from molds. With transmission parts positioned beneath the worktable and molds mounted on top, this configuration ensures easy cleaning and maintenance. The machine employs automatic spray lubrication, longitudinal shaft transmission structure, barrel-type cylindrical indexing mechanism, and gear transmission to guarantee overall stability and quality. Electrical components are controlled through PLC, photoelectric tracking, and servo feed systems. This production line achieves output rates of 90-120 units per minute, suitable for manufacturing cold/hot barrels ranging from 16 to 48 ounces.

| High-speed Intelligent Paper Cup Machine HF – 128S | |

| Weight | 3800 kg |

| Machine packing specifications (without wooden box) | Length: 3200mm x Width: 1450mm x Height: 2100mm |

| Power configuration | Three-phase 380V, 25KW |

| Compressed air configuration | 0.6-0.8MPa,0.5m³/min |

| Production capacity | 90-120 pcs/min |

| Paper type | Single-sided PE / Double-sided PE / PLA |

| Paper weight | 210-330g/㎡ |

| Paper cup specifications | (D1 cup opening) 90-120mm (D2 cup bottom) 60-90mm (H cup height) 135-190mm (h bottom depth) 5-12mm |

| Paper cup detection device | (Optional) |

| Control panel | 7 inches |

| Receiving cup rack | 1000 x 650 x 1600mm |